March 7, 2018

Do you like it?0

March 1, 2018

Do you like it?0

February 28, 2018

Published by jannie at February 28, 2018

Categories

Challenge A leading Malaysian manufacturer of paper-based products was experiencing poor stretch wrap efficiency. The company was experiencing high rates of stretch film breakage, resulting in large amounts of film waste. Due to the poor film strength, the manufacturer had to run wrapping equipment at lower pre-stretch rates. The lower stretch rates resulted in damaged products during shipping and used excessive amounts of film to achieve ideal load containment.

Do you like it?0

February 28, 2018

Published by jannie at February 28, 2018

Categories

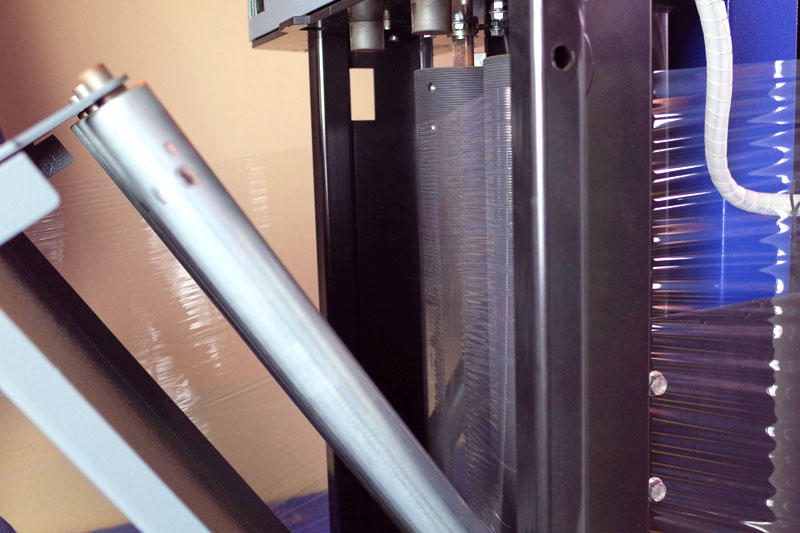

Challenge The Distributor’s packaging solution consisted of an automated packaging line equipped with an automatic rotary arm stretch wrapper. Their heavy products and wrapping procedure were applying more tension than their stretch film could handle. The film was breaking as it stretched to the desired 250%. The film would snap as it came off the roll, or puncture and break if the wrap caught on an extruding edge. The stretch film breaks would interrupt the wrap cycle, shutting down the Distributor’s automated packaging line. The breakdowns in productivity were increasing wrap times and reducing throughput by causing a backup of […]

Do you like it?0

February 28, 2018

February 28, 2018

Published by jannie at February 28, 2018

Categories

Case Study 4 – Increasing Load Retention And Cutting Costs For A Top Taiwanese Beverage Manufacturer

Challenge A Taiwanese leading beverage company approached Respack with a request to increase their pallet load stability whilst not compromising their current costs.

Do you like it?0

February 28, 2018

Published by jannie at February 28, 2018

Categories

Challenge Through the acquisition of 4 separate manufacturing plants, our customer ended up with a range of film suppliers providing a range of different stretch wrapping products on three different types of stretch wrapping machinery. Following this merge, we were approached to audit the pallet stretch wrapping usage across all four facilities to gain an in-depth working knowledge of each sites unique production processes, load profiles and stretch wrap requirements.

Do you like it?0

February 28, 2018

February 28, 2018

Published by jannie at February 28, 2018

Categories

Challenge Pallets of finished concrete blocks are stored outside and exposed to the weather for up to a year prior to use. The traditional stretch film being used was deteriorating over time causing product discoloration, load security concerns and product presentation issues.

Do you like it?0