Case Study 1 - Improving Stretch Wrap Efficiency And Throughput With XPERT™ Power Pre-Stretch Machine Films

Challenge

A leading Malaysian manufacturer of paper-based products was experiencing poor stretch wrap efficiency. The company was experiencing high rates of stretch film breakage, resulting in large amounts of film waste. Due to the poor film strength, the manufacturer had to run wrapping equipment at lower pre-stretch rates. The lower stretch rates resulted in damaged products during shipping and used excessive amounts of film to achieve ideal load containment.

Solution

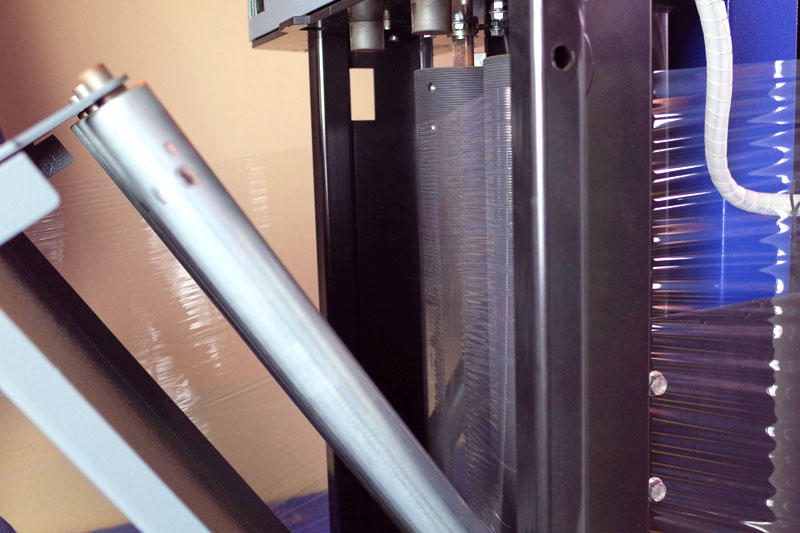

Our Sales Officer visited the manufacturer's facility to conduct an Optimax analysis. The program included a free packaging consultation and a complete review of their existing stretch film operation. The program analyzed the manufacturer’s stretch wrap film, equipment and procedures. Our specialist worked with the manufacturer’s maintenance team to develop new stretch wrap standards and equipment settings. The team was shown what errors to watch for and how to adjust wrapper settings as needed. Following the audit, we provided the manufacturer with sample rolls of a 12um Xpert™ stretch film for testing in their facility.

Results

Improved Throughput and Efficiency

Following the Optimax audit, the company replaced their existing stretch film with Xpert™ film. The new film, paired with the finely tuned settings has helped the customer see great improvements to their stretch wrap throughput and films consumption rates.

With a stronger film and finely tuned wrap process, the manufacturer eliminated film breakage during wrap cycles. With no film breaks, our customer has increased stretch wrapper throughput rates. The down gauged film reduces the amount of downtime for roll changeovers.Reduced Stretch Film Consumption And Improved Per Pallet Cost

With a stronger stretch film, the company has been able to use their stretch film more efficiently. The improvement to wrap strength and stretchability has allowed for a reduction in wraps per load. With fewer individual wraps required, each pallet uses less film. This has increased the Manufacturer’s throughput and lowered their cost per pallet.

Reduced Shipping Damages

The ultra-high quality and strength of Xpert™ film have provided the Manufacturer with increased wrap strength. The increased wrap strength has helped the Manufacturer achieve a higher containment strength or, increased force to load. This increased containment provides sturdy loads that are more stable and will not collapse during handling or transport.