Case Study 7 - Weatherability Optimization For A Korean Concrete Bricks Manufacturer

Challenge

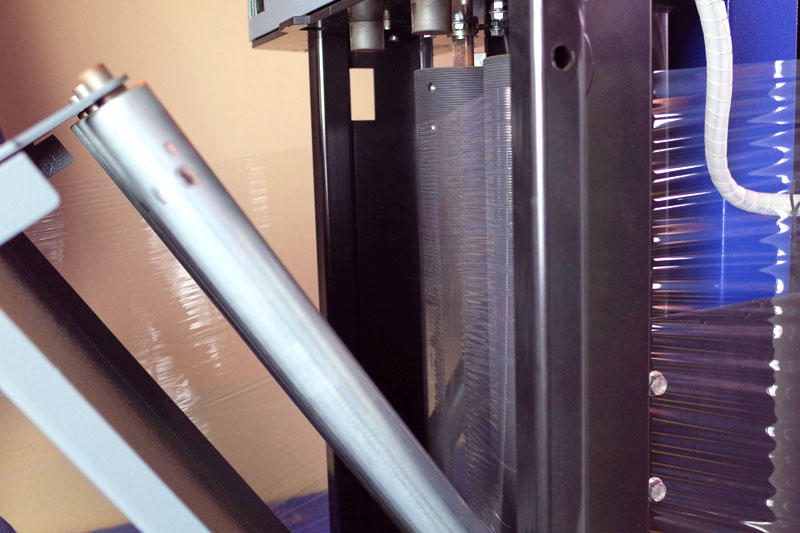

Pallets of finished concrete blocks are stored outside and exposed to the weather for up to a year prior to use. The traditional stretch film being used was deteriorating over time causing product discoloration, load security concerns and product presentation issues.

Solution

We recommended our range of stretch film specially formulated to be used on pallets that are exposed to the elements for long periods of time. Each site was visited and trials were run to ensure the existing wrapping machinery was set up correctly, the film applied suited the pallet load profile and site personnel were trained in the correct application and usage of the new film.

Results

The final outcome was positive with top quality product, securely wrapped and 100% presentable. The combined weather proofing elements of the film meant that not only was the product protected from harmful UV rays, but the added inside cling ensured no water ingress, thus eliminating mold buid-up on the finished blocks.